FIB lamella preparation process

Details of how lamellae are prepared in the FIB.

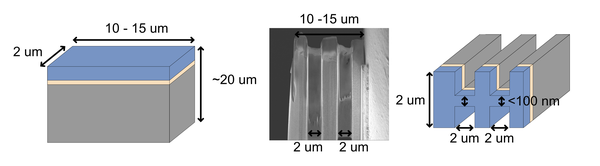

Lamellae are thin, cross-section samples prepared in the FIB-SEM for TEM imaging. The preparation aims to obtain a section of a sample that can be thinned to less than 100 nm for high-resolution TEM imaging. The lamella is cut from the surface of a small sample (typically a 1x1 cm piece) at the dimensions shown in the image below. The steps for FIB require milling with a gallium ion beam, and deposition of material (typically platinum) to serve as protection for the sample, and to 'weld' materials together. Note that, unlike true welding, no heating is involved in this process.

Another consideration is if you would like to do diffraction or align to a zone axis in TEM imaging, then the FIB sample must be prepared along that axis. Be sure to specify the axis you prefer when you request FIB lamella sample preparation.

FIB dimensions

As seen in the TEM image above, the top of the lamella (near the platinum layer) is thinner than the bottom, if the features you wish to observe are deep in your sample, then milling the base of the lamella to be thinner will require more time and can be complicated to achieve depending on the substrate material.

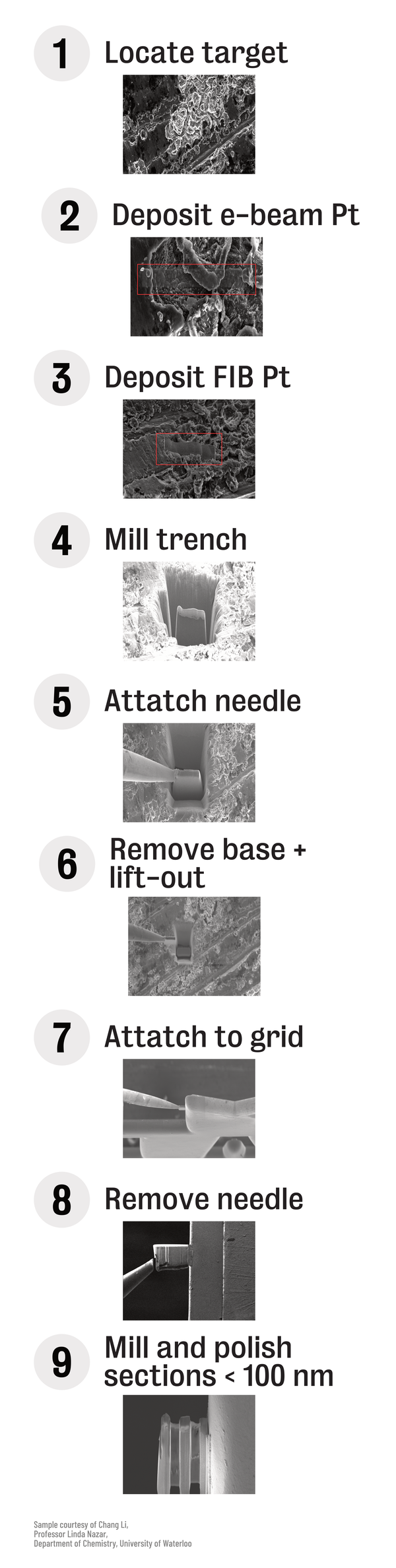

FIB process (simplified)

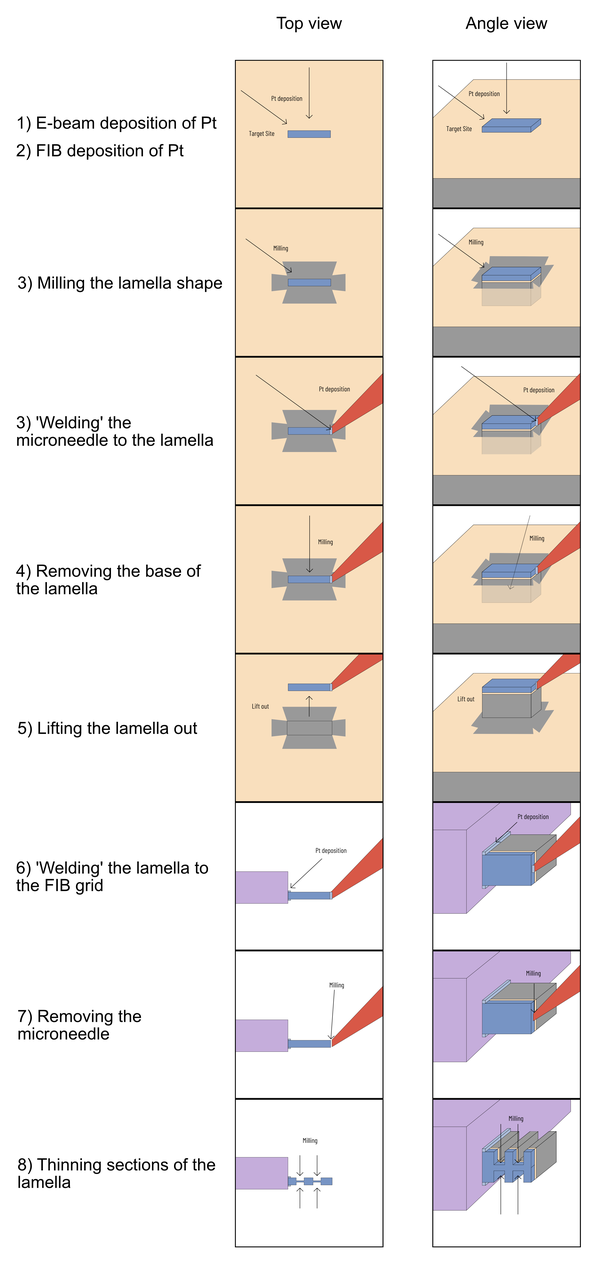

FIB process (example)